Songbo He*, Jessi Osorio Velasco, Julian R. J. Strien, Zhenlei Zhang, Stefanie M. Bianchetti, Parniya Badr, Balaji Sridharan,

Hendrik H. van de Bovenkamp, Robbie H. Venderbosch, Anton Bijl, and Hero Jan Heeres*

Energy and Fuels,2024, 38(10):8740-8748.

https://doi.org/10.1021/acs.energyfuels.3c04733

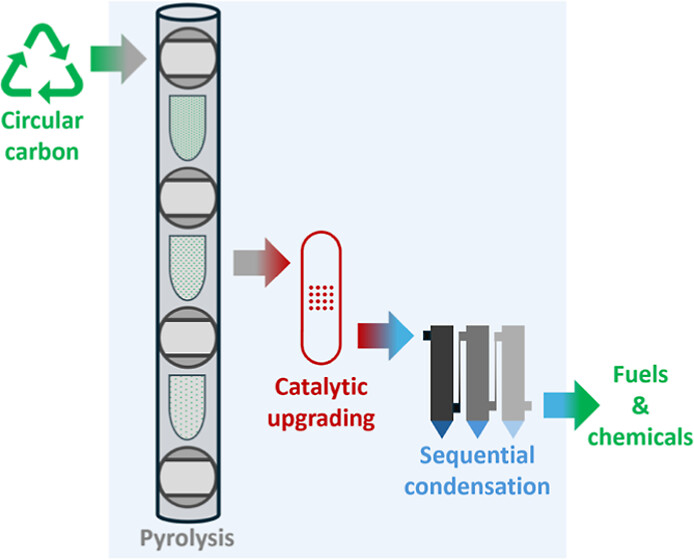

ABSTRACT: Pyrolysis of lignocellulosic biomass and waste plastics has been intensely studied in the last few decades to obtain renewable fuels and chemicals. Various pyrolysis devices have been developed for use in a laboratory setting, operated either in batch or continuously at scales ranging from milligrams per hour to tenths of g per hour. We report here the design and operation of a novel staged free-fall (catalytic) pyrolysis unit and demonstrate that the concept works very well for the (catalytic) pyrolysis of pinewood sawdust, paper sludge, and polypropylene as representative feeds. The unit consists of a vertical tube with a pretreatment section, a pyrolysis section, a solid residue collection section, a gas−liquid separation/collection section, and a catalytic reaction section to optionally perform ex situ catalytic upgrading of the pyrolysis vapor. The sample is placed in a tube, which is transported by gravity through various sections of the unit. It allows for rapid testing with semicontinuous feeding (e.g., 50 g h−1 ) and the opportunity to perform reactions under an (inert) gas (e.g., N2) at atmospheric as well as elevated pressure (e.g., 50 bar). Liquid yields for noncatalytic sawdust pyrolysis at optimized conditions (475 °C and atmospheric pressure) were 63 wt % on biomass intake. A lower yield of 51 wt % (on a biomass basis) was obtained for the noncatalytic pyrolysis of paper sludge, likely due to the presence of minerals (e.g., CaCO3) in the feed. The possibility of using the unit for ex situ catalytic pyrolysis (pyrolysis at 475 °C and catalytic upgrading at 550 °C) was also successfully demonstrated using paper sludge as the feed and H-ZSM-5 as the catalyst (21 wt % catalyst on biomass). This resulted in a biphasic liquid product with 25.6 wt % of an aqueous phase and 11 wt % of an oil phase. The yield of benzene, toluene, and xylenes was 1.9 wt % (on a biomass basis). Finally, the concept was also proven for a representative polyolefin (polypropylene), both noncatalytic as well as in situ catalytic pyrolysis using H-ZSM-5 as the catalyst at 500 °C. The liquid yield of thermal, noncatalytic plastic pyrolysis was as high as 77 wt % on plastic intake, while in situ catalytic pyrolysis gave a combined 7.8 wt % yield of benzene, toluene, and xylenes on plastic intake.

摘要:过去几十年,为获取可再生燃料与化学品,木质纤维素生物质及废塑料的热解技术被广泛研究。各类实验室规模的热解装置(间歇式或连续式,处理量从每小时毫克至数十克不等)应运而生。本文报道了一种新型分段自由落体(催化)热解装置的设计与运行,并以松木锯屑、造纸污泥和聚丙烯为代表原料,验证了该装置在(催化)热解中的优异性能。该装置由竖直管体构成,包含预处理段、热解段、固体残渣收集段、气液分离/收集段以及可选配的催化反应段(用于对热解蒸气进行非原位催化提质)。样品置于管中,在重力作用下通过装置各区域。装置支持半连续进料(如50 g h⁻¹),并可在(惰性)气体氛围(如N₂)下,于常压及加压条件(如50 bar)进行反应。在优化条件(475 ℃、常压)下,锯屑非催化热解的液体产率达63 wt %(基于原料生物质)。造纸污泥的非催化热解产率较低,为51 wt %(基于生物质),这可能是由于原料中含矿物质(如CaCO₃)所致。以造纸污泥为原料、H-ZSM-5为催化剂(催化剂用量为生物质的21 wt %),成功验证了装置用于非原位催化热解(热解段475 ℃、催化段550 ℃)的可行性,获得双相液体产物,其中水相25.6 wt %、油相11 wt %,苯、甲苯和二甲苯的总产率为1.9 wt %(基于生物质)。最后,以典型聚烯烃(聚丙烯)为对象,验证了该装置在非催化热解(500 ℃)及原位催化热解(使用H-ZSM-5催化剂,500 ℃)中的适用性。塑料非催化热解的液体产率高达77 wt %(基于原料塑料),而原位催化热解中苯、甲苯和二甲苯的总产率达7.8 wt %(基于原料塑料)。