Songbo He, Frederike Gerda Hiltje Klein, Thomas Sjouke Kramer, Anshu Chandel, Zhuorigebatu Tegudeer, Andre Heeres, Hero Jan Heeres*

ACS Sustainable Chem. Eng, 2021,9:1128-1141

https://dx.doi.org/10.1021/acssuschemeng.0c06181

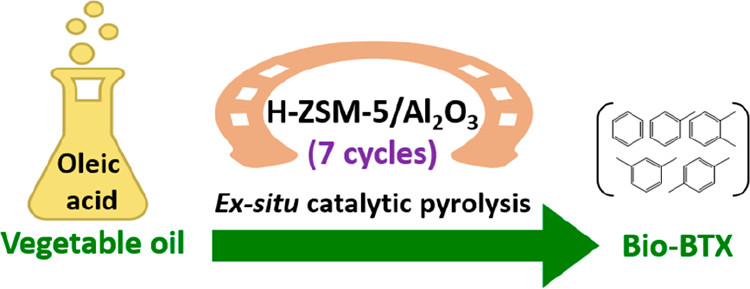

ABSTRACT: The catalytic conversion of oleic acid to aromatics (benzene, toluene, and xylenes, BTX) over a granular H-ZSM-5/Al2O3 catalyst (ϕ 1.2–1.8 mm, 10 g loading) was investigated in a continuous bench-scale fixed-bed reactor (10 g oleic acid h–1). A peak carbon yield of aromatics of 27.4% was obtained at a catalyst bed temperature of 550 °C and atmospheric pressure. BTX was the major aromatics formed (peak carbon yield was 22.7%), and a total BTX production of 1000 mg g–1 catalyst was achieved within a catalyst lifetime of 6.5 h for the fresh catalyst. The catalyst was deactivated due to severe coke deposition (ca. 22.1 wt % on the catalyst). The used catalyst was reactivated by an ex situ oxidative regeneration at 680 °C in air for 12 h. The regenerated catalyst was subsequently recycled, and in total, 7 cycles of reaction-regeneration were performed. A gradual decrease in the peak carbon yield of BTX was observed with reaction-regeneration cycles (e.g., to 16.3% for the catalyst regenerated for 6 times). However, the catalyst lifetime was remarkably prolonged (e.g., >24 h), leading to a significantly enhanced total BTX production (e.g., 3000 mg g–1 catalyst in 24 h). The fresh, used, and regenerated catalysts were characterized by N2 and Ar physisorption, XRD, HR-TEM-EDX, 27Al, and 29Si MAS ssNMR, NH3-TPD, TGA, and CHN elemental analysis. Negligible changes in textural properties, crystalline structure, and framework occurred after one reaction-regeneration cycle, except for a slight decrease in acidity. However, dealumination of the H-ZSM-5 framework was observed after 7 cycles of reaction-regeneration, leading to a decrease in microporosity, crystallinity, and acidity. Apparently, these changes are not detrimental for catalyst activity, and actually, the lifetime of the catalyst increases, rationalized by considering that coke formation rates are retarded when the acidity is reduced.

摘要:在连续固定床反应器(油酸进料速率10克/小时)中,采用颗粒状H-ZSM-5/Al₂O₃催化剂(粒径1.2–1.8毫米,装填量10克)研究了油酸催化转化为芳烃(苯、甲苯和二甲苯,统称BTX)的过程。在催化剂床层温度550 °C、常压条件下,获得了27.4%的芳烃峰值碳收率,其中BTX为主要芳烃产物(峰值碳收率为22.7%)。新鲜催化剂在6.5小时寿命期内实现了1000mg/g催化剂的总BTX产量。催化剂因严重的积碳(约22.1 wt%)而失活。使用后的催化剂通过在空气中、680 °C下进行12小时异位氧化再生恢复活性,并随后循环使用,共完成7次反应-再生循环。随着反应-再生循环次数的增加,BTX峰值碳收率逐渐下降(例如,再生6次后降至16.3%),但催化剂寿命显著延长(例如,超过24小时),从而大幅提高了总BTX产量(例如,24小时内达3000毫克·克⁻¹催化剂)。通过N₂和Ar物理吸附、XRD、HR-TEM-EDX、²⁷Al和²⁹Si魔角旋转固态核磁共振、NH₃-TPD、热重分析及CHN元素分析对新鲜、使用后和再生催化剂进行了表征。结果表明,单次反应-再生循环后,催化剂的织构性质、晶体结构和骨架基本保持不变,仅酸度略有下降;但在完成7次循环后,观察到H-ZSM-5骨架发生脱铝,导致微孔性、结晶度和酸度降低。值得注意的是,这些变化并未损害催化剂活性,反而因酸度降低延缓了积碳形成速率,从而使催化剂寿命得以延长。