Songbo He, Thomas Sjouke Kramer, Dian Sukmayanda Santosa, Andre Heeres, Hero Jan Heeres*

Green Chemistry, 2022, 24: 941-949

https://doi.org/10.1039/d1gc03531b

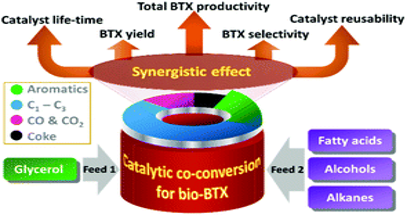

ABSTRACT: Glycerol is an attractive bio-based platform chemical that can be converted to a variety of bio-based chemicals. We here report a catalytic co-conversion strategy where glycerol in combination with a second (bio-)feed (fatty acids, alcohols, alkanes) is used for the production of bio-based aromatics (BTX). Experiments were performed in a fixed bed reactor (10 g catalyst loading and WHSV of (co-)feed of 1 h−1) at 550 °C using a technical H-ZSM-5/Al2O3 catalyst. Synergistic effects of the co-feeding on the peak BTX carbon yield, product selectivity, total BTX productivity, catalyst life-time, and catalyst regenerability were observed and quantified. Best results were obtained for the co-conversion of glycerol and oleic acid (45/55 wt%), showing a peak BTX carbon yield of 26.7 C%. The distribution of C and H of the individual co-feeds in the BTX product was investigated using an integrated fast pyrolysis-GC-Orbitrap MS unit, showing that the aromatics are formed from both glycerol and the co-feed. The results of this study may be used to develop optimized co-feeding strategies for BTX formation.

摘要:甘油是一种具有吸引力的生物基平台化合物,可转化为多种生物基化学品。本文报道了一种催化共转化策略,即甘油与第二种生物质原料(脂肪酸、醇类、烷烃)结合用于生产生物基芳烃(苯、甲苯和二甲苯,简称BTX)。实验在固定床反应器中进行,使用工业级H-ZSM-5/Al₂O₃催化剂,在550 °C、催化剂装填量为10克、进料重量空速为1 h⁻¹的条件下进行。研究观察并量化了共进料对BTX峰值碳收率、产物选择性、总BTX产率、催化剂寿命及催化剂再生能力产生的协同效应。最佳结果来自甘油与油酸(质量比45/55)的共转化,其BTX峰值碳收率达到26.7%。通过集成快速热解-气相色谱-Orbitrap质谱仪对BTX产物中碳和氢的来源分布进行分析,表明芳烃由甘油和共进料共同形成。本研究结果可用于开发优化的BTX形成共进料策略。