Songbo He, Frederike Gerda Hiltje Klein, Thomas Sjouke Kramer, Anshu Chandel, Zhuorigebatu Tegudeer, Andr´e Heeres, Hero Jan Heeres*

Applied Catalysis A, General, 2022, 632: 118486

https://doi.org/10.1016/j.apcata.2022.118486

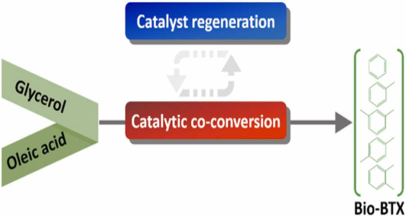

ABSTRACT: The catalytic co-conversion of glycerol and oleic acid (45/55 wt%) to bio-based aromatics (benzene, toluene, and xylenes, bio-BTX) over a technical H-ZSM-5/Al2O3 catalyst in a fixed-bed reactor was investigated with special attention to catalyst deactivation phenomena. The spent catalysts after a time on stream (TOS) of 12 h were regenerated by an ex-situ oxidative treatment to remove coke and reused for another run. In total, 5 reaction-regeneration cycles were performed. The performance and characteristics of the fresh and regenerated catalysts were determined to identify and quantify the effects of co-feeding on catalyst stability and regenerability. The performance of the catalyst changes upon the number of reaction-regeneration cycles. Despite a negative effect on the peak BTX yield, a remarkable improvement in catalyst stability was found, leading to higher BTX productivity (1260–1505 gBTX gcat-1 for the regenerated catalysts during a TOS of 12 h vs. 834 gBTX gcat-1 for the fresh one during a life-time of 11 h). Detailed catalyst characterization studies show irreversible changes in the catalyst structure after reaction-regeneration cycle(s), such as textural property, crystal structure, framework, and acidity, which impact catalyst performance.

摘要:本研究在固定床反应器中,采用工业级H-ZSM-5/Al₂O₃催化剂,考察了甘油与油酸(质量比45:55)共转化制备生物基芳烃(苯、甲苯和二甲苯,即bio-BTX)的过程,重点分析了催化剂失活现象。反应持续12小时后对失活催化剂进行异位氧化再生以去除积碳,并完成5次反应-再生循环。通过对比新鲜与再生催化剂的性能及特性,明确了共进料对催化剂稳定性和可再生性的影响。研究发现,催化剂性能随反应-再生循环次数的增加而变化:尽管共进料会降低BTX峰值产率,但显著提升了催化剂稳定性,使再生催化剂在12小时内的BTX产率(1260–1505 gBTX/gcat)高于新鲜催化剂在11小时寿命内的产率(834 gBTX/gcat)。详细的催化剂表征表明,反应-再生循环会导致催化剂结构(如织构性质、晶体结构、骨架和酸性)发生不可逆变化,进而影响其催化性能。