Songbo He, Thomas Sjouke Kramer, Frederike Gerda Hiltje Klein, Anshu Chandel, Zhuorigebatu Tegudeer, Andre Heeres, Chuncheng Liu, Evgeny Pidko, Hero Jan Heeres*

Applied Catalysis A: General,629, 118393

https://doi.org/10.1016/j.apcata.2021.118393

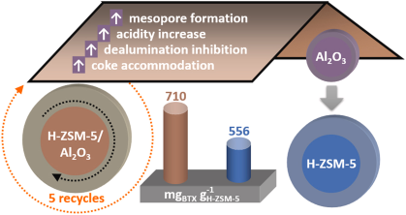

ABSTRACT: The catalytic conversion of glycerol to aromatics (GTA, e.g., benzene, toluene, and xylenes, BTX) over a shaped H-ZSM-5/Al2O3 (60/40 wt%) catalyst was investigated in a continuous fixed-bed reactor to study the addition of the Al2O3 binder in the catalyst formulation on catalyst performance. The experiments were performed under N2 at 550 °C, a WHSV of glycerol (pure) of 1 h−1, and atmospheric pressure. The spent H-ZSM-5/Al2O3 catalysts were reused after an oxidative regeneration at 680 °C and in total 5 reaction-regeneration cycles were performed. Catalyst characterization studies show that the addition of the Al2O3 binder does not affect the surface area and crystallinity of the formulation, but increases the total pore volume (mesopores in particular) and total acidity (Lewis acidity in particular). The H-ZSM-5/Al2O3 (60/40 wt%) catalyst shows a considerably prolonged catalyst life-time (8.5 vs. 6.5 h for H-ZSM-5), resulting in a significant increase in the total BTX productivity (710 vs. 556 mg g−1 H-ZSM-5). Besides, the addition of the Al2O3 binder retards irreversible deactivation. For instance, after 3 regenerations, catalyst performance is comparable to the fresh one. However, after 4 regenerations, some irreversible catalyst deactivation occurs, associated with a reduction in total pore volume, crystallinity, and acidity (Brønsted acidity in particular), and meso-porosity of the Al2O3 binder. This study shows that both the stability and reusability of H-ZSM-5-based catalysts for GTA are remarkably enhanced when using a suitable binder.

摘要:为研究Al₂O₃粘结剂对催化剂性能的影响,本文在连续固定床反应器中考察了甘油在成型H-ZSM-5/Al2O3(60/40 wt%)催化剂上催化转化为芳烃(GTA,如苯、甲苯和二甲苯,即BTX)的反应过程。实验在N₂氛围、550 °C、甘油空速(WHSV)为1 h⁻¹及常压条件下进行。对使用后的H-ZSM-5/Al2O3催化剂在680 °C进行氧化再生,并完成总计5次反应-再生循环。表征结果表明,Al2O3粘结剂的添加不影响催化剂体系的比表面积和结晶度,但显著增加了总孔体积(尤其是介孔)和总酸量(以路易斯酸为主)。与纯H-ZSM-5相比,H-ZSM-5/Al₂O₃(60/40 wt%)催化剂的寿命明显延长(8.5 h vs. 6.5 h),BTX总产率显著提高(710 vs. 556 mg/g H-ZSM-5)。此外,Al₂O₃粘结剂的引入延缓了催化剂的不可逆失活:经历3次再生后,催化剂性能仍与新鲜催化剂相当;但经过4次再生后,由于总孔体积、结晶度、酸量(尤其是布朗斯特酸)以及Al2O3粘结剂介孔结构的减少,出现部分不可逆失活。本研究证明,使用合适的粘结剂可显著提升H-ZSM-5基催化剂在GTA反应中的稳定性和可重复使用性。