Fukang Wang, Thomas Sjouke Kramer, Bin Yan, Lin Zhu, Yuezhao Zhu, Andre Heeres, Diana Ciolca, Hero Jan Heeres*, Songbo He*

ACS Sustainable Chemistry and Engineering, 2024, 12(15): 5731-5737

https://doi.org/10.1021/acssuschemeng.4c00451

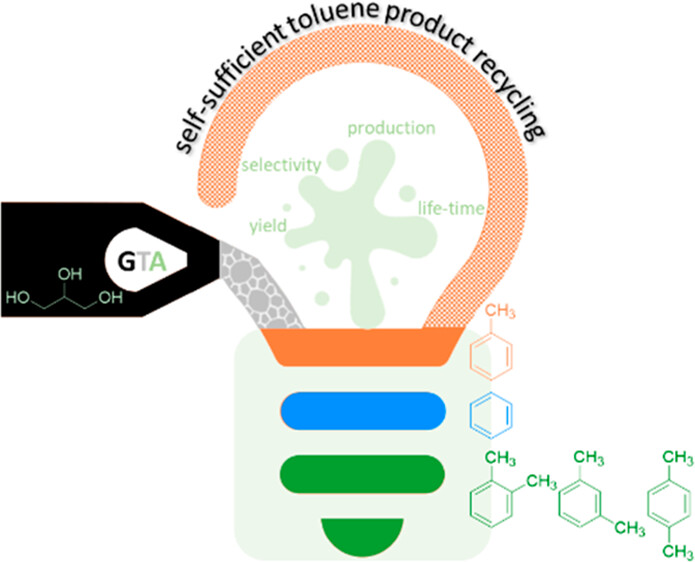

ABSTRACT: The catalytic coconversion of glycerol and toluene (93/7 wt %) over a technical H-ZSM-5/Al2O3 (60−40 wt %) catalyst was studied, aiming for enhanced production of biobased benzene, toluene, and xylenes (bio-BTX). When using glycerol/toluene cofeed with a mass ratio of 93/7 wt %, a peak BTX carbon yield of 29.7 ± 1.1 C.% (at time on stream (TOS) of 1.5−2.5 h), and an overall BTX carbon yield of 28.7 C.% (during TOS of 8.5 h) were obtained, which are considerably higher than those (19.1 ± 0.4 C.% and 11.0 C.%) for glycerol alone. Synergetic effects when cofeeding toluene on the peak and overall BTX carbon yields were observed and quantified, showing a relative increase of 3.1% and 30.0% for the peak and overall BTX carbon yield (based on the feedstock). These findings indicate that the strategy of cofeeding in situ produced toluene for the conversion of glycerol to aromatics has potential to increase BTX yields. In addition, BTX production on the catalyst (based on the fresh catalyst during the first run for TOS of 8.5 h and without regeneration) is significantly improved to 0.547 ton ton−1 catalyst (excluding the 76% of toluene product that is 0.595 ton ton−1 catalyst for the recycle in the cofeed) for glycerol/toluene cofeed, which was 0.426 ton ton−1 catalyst for glycerol alone. In particular, this self-sufficient toluene product recycling strategy is advantageous for the production and selectivity (relative increase of 84.4% and 43.5% during TOS of 8.5 h) of biobased xylenes.

摘要:本研究考察了甘油与甲苯(质量比93:7)在工业级H-ZSM-5/Al₂O₃(60:40 wt%)催化剂上的共转化反应,旨在提高生物基苯、甲苯和二甲苯(bio-BTX)的产率。当采用质量比为93:7的甘油/甲苯共进料时,获得了29.7 ± 1.1 C.%的BTX峰值碳收率(运行时间1.5–2.5小时)和28.7 C.%的总BTX碳收率(运行时间8.5小时),显著高于单独使用甘油时的相应值(19.1 ± 0.4 C.%和11.0 C.%)。研究观察并量化了甲苯共进料对峰值和总BTX碳收率的协同促进效应,结果显示基于原料计算的峰值和总BTX碳收率分别相对提高了3.1%和30.0%。这些发现表明,通过共进料方式利用原位生成的甲苯来促进甘油芳构化,是具有提高BTX产率潜力的有效策略。此外,催化剂单位质量的BTX产量(基于新鲜催化剂在首次运行8.5小时且未再生条件下计算)在甘油/甲苯共进料时显著提升至0.547吨/吨催化剂(若扣除占产物76%且可循环进料的甲苯对应产量0.595吨/吨催化剂),而单独使用甘油时该值为0.426吨/吨催化剂。特别值得注意的是,这种甲苯产物自循环策略对生物基二甲苯的生产和选择性具有显著优势(运行8.5小时内分别相对提高84.4%和43.5%)。