Cui Ouyang, Jianwei Li*, Yaqi Qu, Song Hong, Songbo He*

Green Energy & Environment, 8(4), 1161-1173

https://doi.org/10.1016/j.gee.2022.01.007

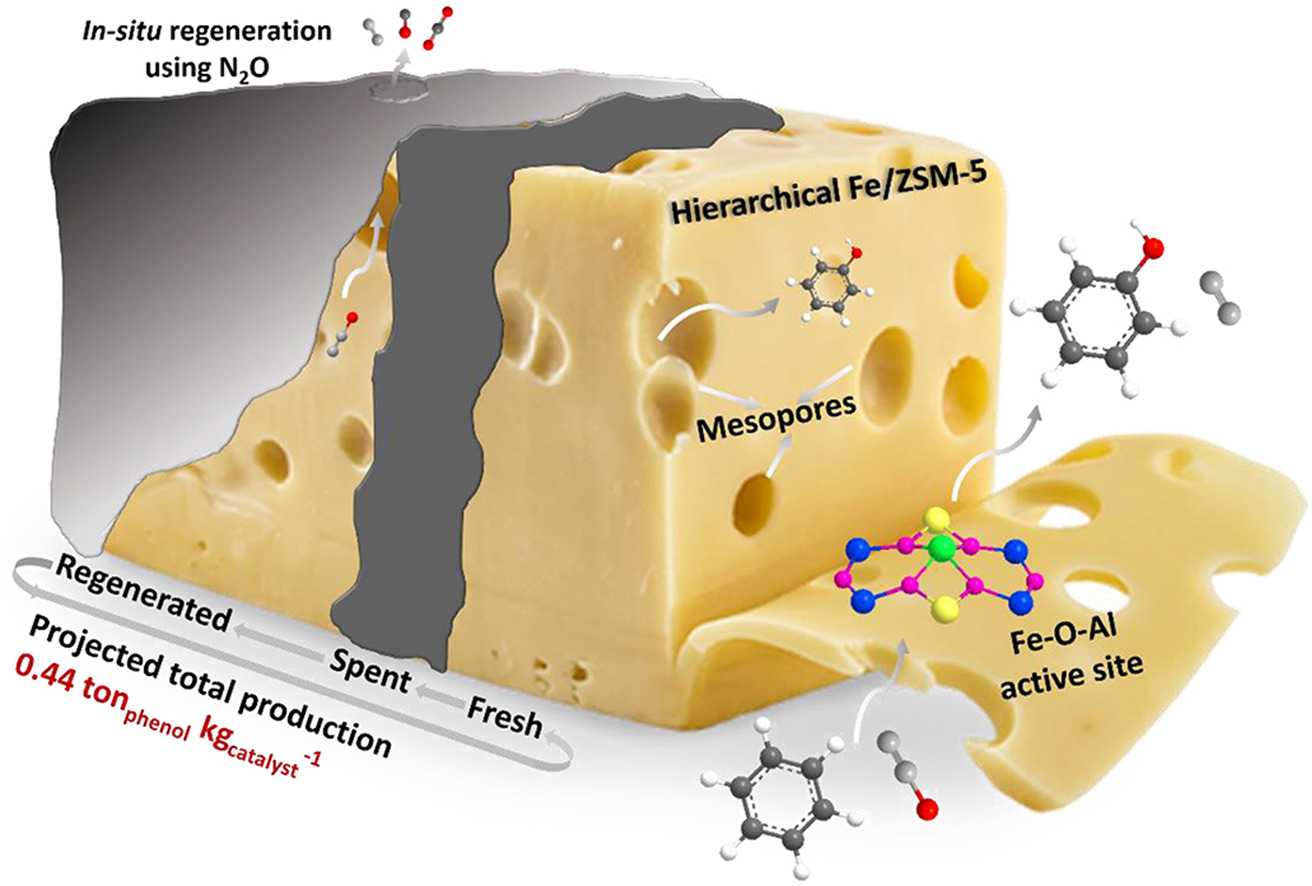

ABSTRACT: Catalytic oxidation of benzene with N2O to phenol over the hierarchical and microporous Fe/ZSM-5-based catalysts in a continuous fixed-bed reactor was investigated. The spent catalyst was in-situ regenerated by an oxidative treatment using N2O and in total 10 reaction-regeneration cycles were performed. A 100% N2O conversion, 93.3% phenol selectivity, and high initial phenol formation rate of 16.49 ± 0.06 mmolphenol gcatalyst−1 h−1 at time on stream (TOS) of 5 min, and a good phenol productivity of 147.06 mmolphenol gcatalyst−1 during catalyst life-time of 1800 min were obtained on a fresh hierarchical Fe/ZSM-5-Hi2.8 catalyst. With the reaction-regeneration cycle, N2O conversion is fully recovered within TOS of 3 h, moreover, the phenol productivity was decreased ca. 2.2 ± 0.8% after each cycle, leading to a total phenol productivity of ca. 0.44 tonphenol kgcatalyst−1 estimated for 300 cycles. Catalyst characterizations imply that the coke is rapidly deposited on catalyst surface in the initial TOS of 3 h (0.28 mgc gcatalyst−1 min−1) and gradually becomes graphitic during the TOS of 30 h with a slow formation rate of 0.06 mgc gcatalyst−1 min−1. Among others (e.g., the decrease of textural property and acidity), the nearly complete coverage of the active Fe-O-Al sites by coke accounts for the main catalyst deactivation. Besides these reversible deactivation characteristics related to coking, the irreversible catalyst deactivation is also observed with the reaction-regeneration cycle. The latter is reflected by a further decreased amount of the active Fe-O-Al sites, which agglomerate on catalyst surface with the cycle, likely associated with the hard coke residue that is not completely removed by the regeneration.

摘要:本研究在连续固定床反应器中,考察了基于层级结构与微孔Fe/ZSM-5的催化剂上以一氧化二氮(N₂O)为氧化剂催化氧化苯制苯酚的反应性能。采用N₂O对失活催化剂进行原位氧化再生,共完成10次反应-再生循环。结果表明:新鲜层级结构催化剂Fe/ZSM-5-Hi2.8在反应时间(TOS)5分钟时即实现100%的N₂O转化率、93.3%的苯酚选择性,以及16.49±0.06 mmol苯酚·g催化剂⁻¹·h⁻¹的高初始生成速率;在1800分钟催化剂寿命内,苯酚产率达147.06 mmol苯酚/g催化剂。经历反应-再生循环后,N₂O转化率在3小时内可完全恢复,但每循环一次苯酚产率下降约2.2±0.8%;据估算,300次循环后累计苯酚产率约为0.44吨苯酚/kg催化剂。催化剂表征显示,积碳在初始3小时内快速沉积(速率0.28 mg积碳/g催化剂/min),随反应进行至30小时,积碳逐渐石墨化,形成速率降至0.06 mg积碳/g催化剂/min。除织构性质与酸性降低外,活性位点Fe-O-Al近乎被积碳完全覆盖是催化剂失活的主因。除积碳相关的可逆失活外,循环过程中还观察到不可逆失活,表现为活性Fe-O-Al位点数量进一步减少并在催化剂表面团聚,可能与再生未能完全去除的硬质积碳残留有关。